News

By Hermione

By Hermione

PVDF Coated Aluminum Coil For Industrial Roofing

Industrial roofs are expected to stay watertight and visually consistent for decades while facing UV radiation, temperature cycling, wind-borne dust, and chemical exposure from industrial atmospheres. PVDF coated aluminum coil is positioned as a high-durability, coil-coated material engineered for these demanding roofing systems, including metal roof panels, standing seam profiles, insulated sandwich panels, and large-span warehouse and plant roofing.

Why aluminum coil is a practical substrate for industrial roofs

Industrial roofing favors materials that are light, formable, and stable under outdoor service. Aluminum coil provides a strong balance of performance and processing efficiency:

Low density supports lightweight roof assemblies, reducing structural load and easing installation and handling.

Natural corrosion resistance from the aluminum oxide film provides a robust base for long-life protective coatings.

High formability enables roll-forming into trapezoidal sheets, rib profiles, and standing seam panels with consistent geometry.

Good thermal conductivity supports faster heat dissipation; when paired with reflective colors or cool-roof pigments, it can reduce surface temperature.

In practice, alloy selection is matched to profile complexity and mechanical requirements. Common industrial roofing choices include 3xxx/5xxx series for improved strength and forming stability, with temper selected to balance roll-formability and dent resistance.

PVDF coating systems: built for UV, chemicals, and long service life

The differentiator for industrial roofing is often not the metal substrate itself but the coating system that protects it. A fluorocarbon coating based on PVDF resin (typically 70% PVDF) is widely used when long-term exterior durability is required.

A typical PVDF coil coating build-up is engineered as a system rather than a single layer:

Pretreatment conversion layer (non-chrome or chrome-free options): improves adhesion and underfilm corrosion resistance.

Primer: supports edge protection, bonding, and forming performance; contributes to corrosion resistance when roofing sheets are fastened or cut.

PVDF topcoat: provides UV stability, chemical resistance, gloss retention, and color stability.

Optional back coat/service coat: optimized for underside protection, insulation contact compatibility, and improved processing through roll-forming.

PVDF's molecular structure is highly resistant to UV-driven polymer degradation, which translates to slower chalking and fading compared with standard polyester systems. For roofs exposed to coastal salt spray, acid rain, or industrial emissions, PVDF coatings also help reduce staining and maintain appearance over time.

For product detail alignment with specific PVDF resin systems and available finish options, the material is commonly supplied as PVDF Coated Aluminum Coil for exterior roofing and facade-grade requirements.

How coil coating manufacturing supports consistent roofing performance

Roofing panels may cover tens of thousands of square meters in a single project; consistency from coil to coil is essential. Coil coating is designed to deliver repeatable film build, color, and cure.

Key manufacturing controls that affect industrial roof reliability include:

Surface preparation and cleaning to remove rolling oils and ensure uniform pretreatment reaction.

Pretreatment control (bath chemistry, conductivity, temperature, dwell time) to stabilize adhesion and corrosion resistance.

Coating application via precision roll coating to achieve target dry film thickness and low variation across width.

Oven curing with controlled peak metal temperature (PMT) to fully crosslink primer and topcoat without overbake (which can reduce flexibility) or underbake (which can compromise chemical resistance).

Inline inspection for gloss, color delta, film thickness, pinholes, and surface defects, supporting stable roll-forming behavior.

Forming is a real-world stress test for coated coil. Proper PVDF system design targets high flexibility and adhesion so that bending, hemming, and roll-forming do not create microcracks that become corrosion initiation sites at ribs, seams, and fastener zones.

Core specifications for PVDF coated aluminum coil used in industrial roofing

Below is a practical specification window widely used for industrial roof panel production. Final selection should be matched to profile design, span, fastening method, and local climate.

| Item | Typical Range / Options |

|---|---|

| Aluminum alloy | 3003, 3004, 3105, 5005, 5052 (others available on request) |

| Temper | H14, H16, H24 (selected per forming and strength needs) |

| Thickness | 0.30-1.20 mm (common roofing: 0.50–0.90 mm) |

| Width | 600-1600 mm |

| Length | 1000-16000 mm |

| Coating type | 70% PVDF topcoat + primer (coil coating system) |

| Topcoat thickness (dry) | 20-25 μm (typical) |

| Primer thickness (dry) | 5-8 μm (typical) |

| Back coat | 5-10 μm (service coat) or per application |

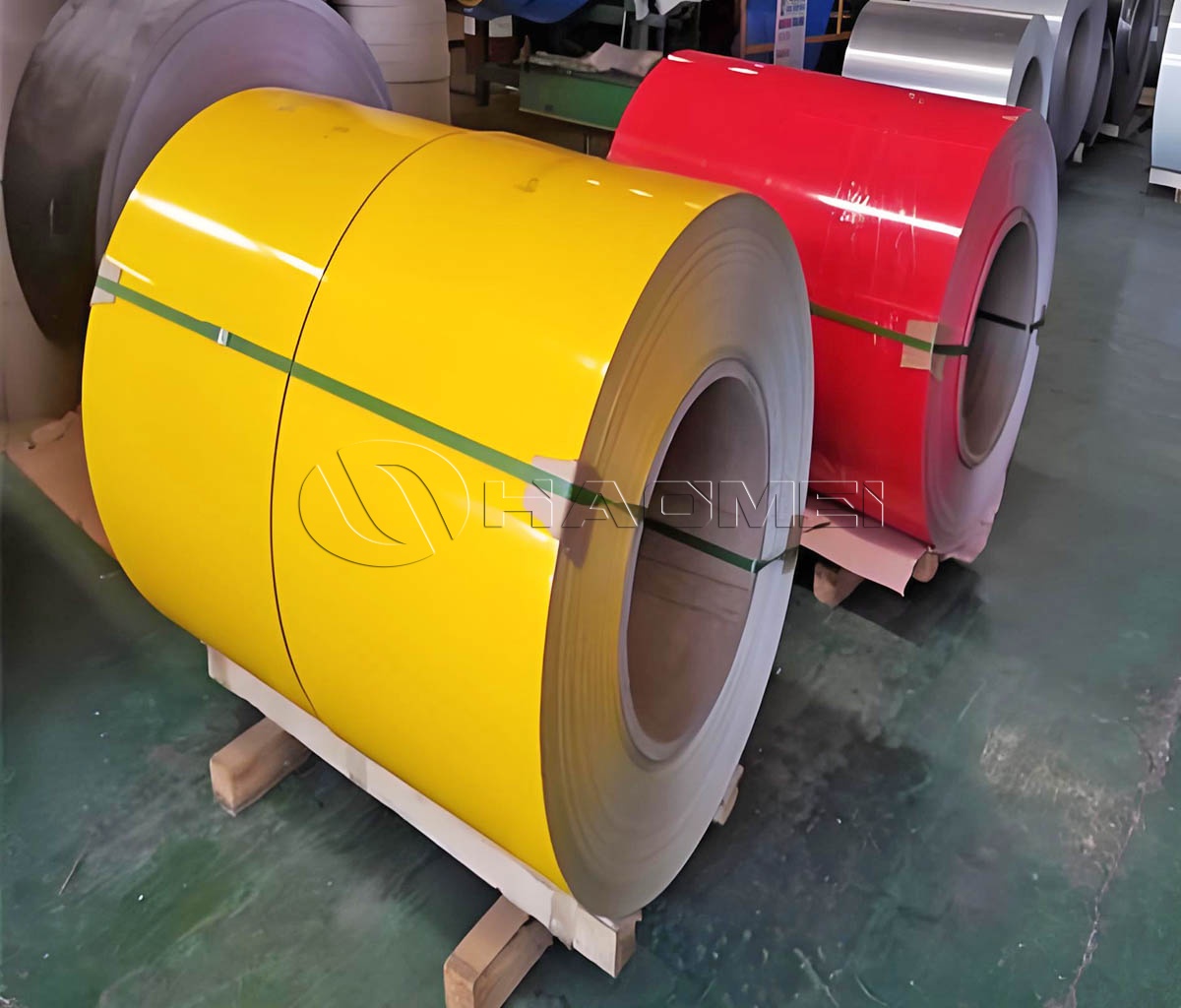

| Finish | Solid, metallic; gloss per request |

| Color | RAL/Pantone/custom; ΔE control per agreement |

| Surface options | Smooth, lightly textured; protective film optional |

| Standards / testing (typical) | Film thickness, adhesion (cross-hatch), T-bend, impact, pencil hardness, MEK rub, salt spray, humidity, QUV |

| MOQ | 1-3 tons |

Practical roofing applications and design considerations

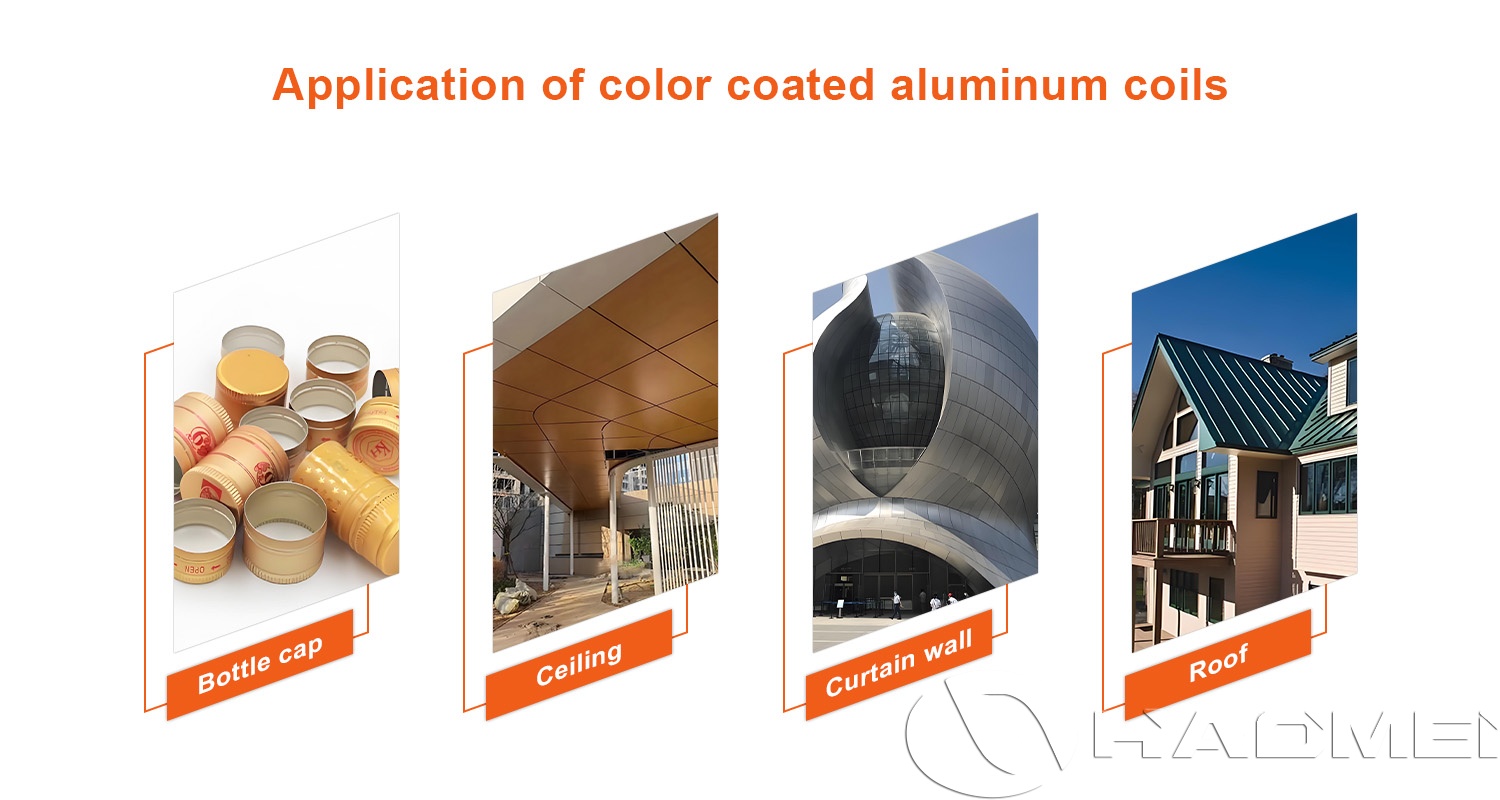

PVDF coated aluminum coil is commonly processed into:

Standing seam roof panels for logistics centers and large-span plants, where long service life and appearance retention are critical.

Trapezoidal and corrugated sheets for general industrial buildings, balancing stiffness and fast installation.

Insulated sandwich panel skins, where coating integrity must withstand profiling and contact with core materials.

Roof accessories (flashings, ridge caps, gutters) requiring consistent color match and forming reliability.

To make the coating system deliver its full value in the field, industrial roofing design typically accounts for:

Edge and cut protection: using compatible sealants, proper lap design, and minimizing standing water at cut edges.

Fastener and washer compatibility: preventing galvanic issues and reducing stress concentration around fixings.

Thermal movement: aluminum's thermal expansion is managed through sliding clips, panel length strategy, and seam design.

Chemical exposure mapping: areas near exhaust stacks, cooling towers, or process vents may require stricter coating thickness control or additional protective detailing.

Where project economics favor a shorter design life or lower UV exposure, polyester systems can be considered; however, for long-life industrial roofs in harsh climates, PVDF remains a common benchmark. For comparison across coating families used in coil-coated roofing materials, options are typically organized under Products for substrate and coating system selection.

-

Pvdf Coated Aluminum Coil For Facades

PVDF coated aluminum coil for facades delivers long-lasting color, corrosion resistance, and formability for architectural cladding, panels, and profiles.

2026-01-08

-

1200 Color Coated Aluminum Coil for Building Facade

1200 color-coated aluminum coils for building exterior walls, featuring PE or PVDF coatings, offer excellent weather resistance, decorative appeal, and processing performance.

2025-12-25

-

PVDF Coated Aluminum Coil Fire Rating Standards

Learn how PVDF coated aluminum coil supports fire rating standards such as EN 13501-1 and ASTM E84, covering coating systems, processes and test-critical details.

2026-01-30