News

By Hermione

By Hermione

1100 Color-Coated Aluminum Coils for Automotive Interior Decoration

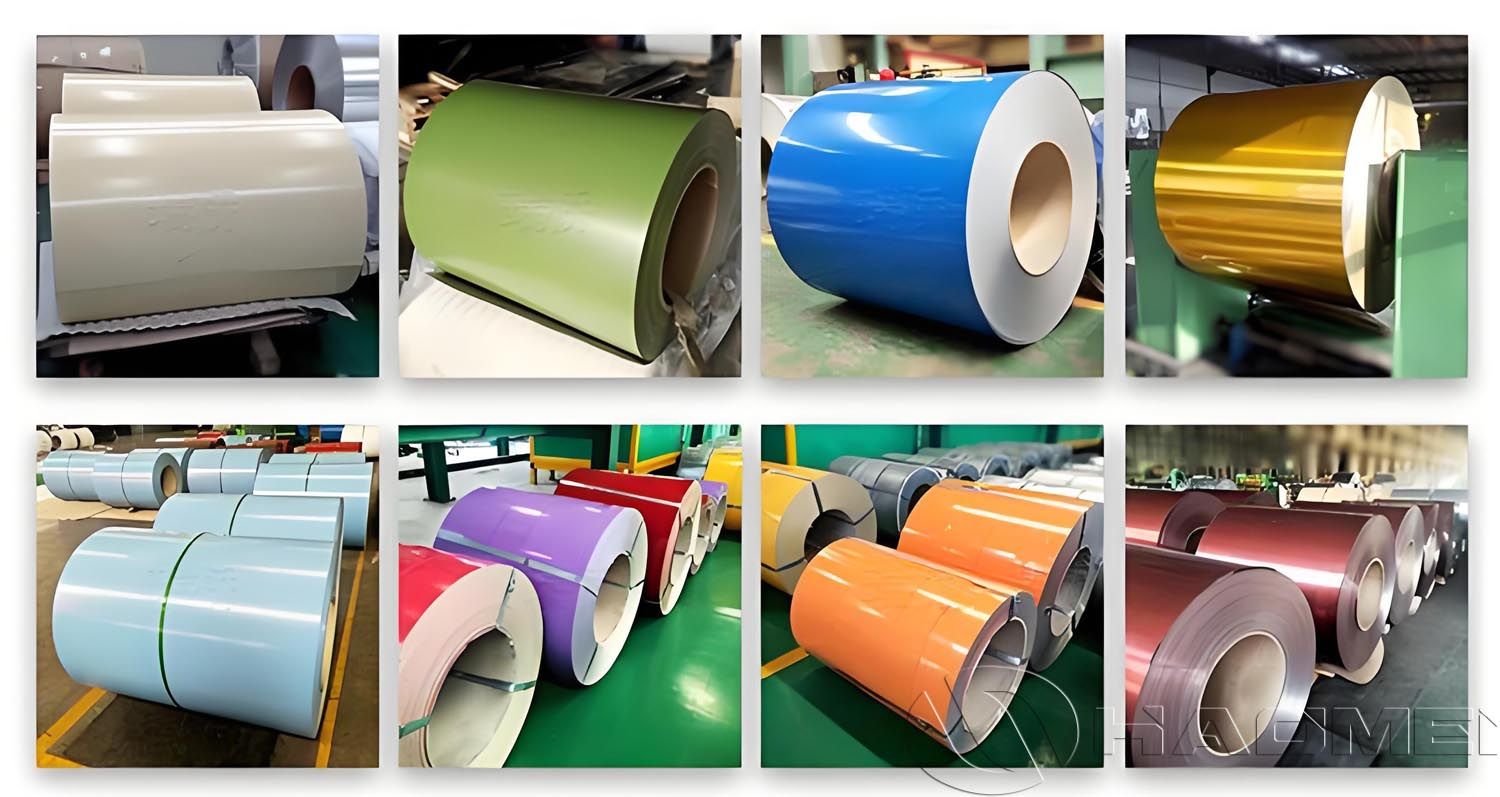

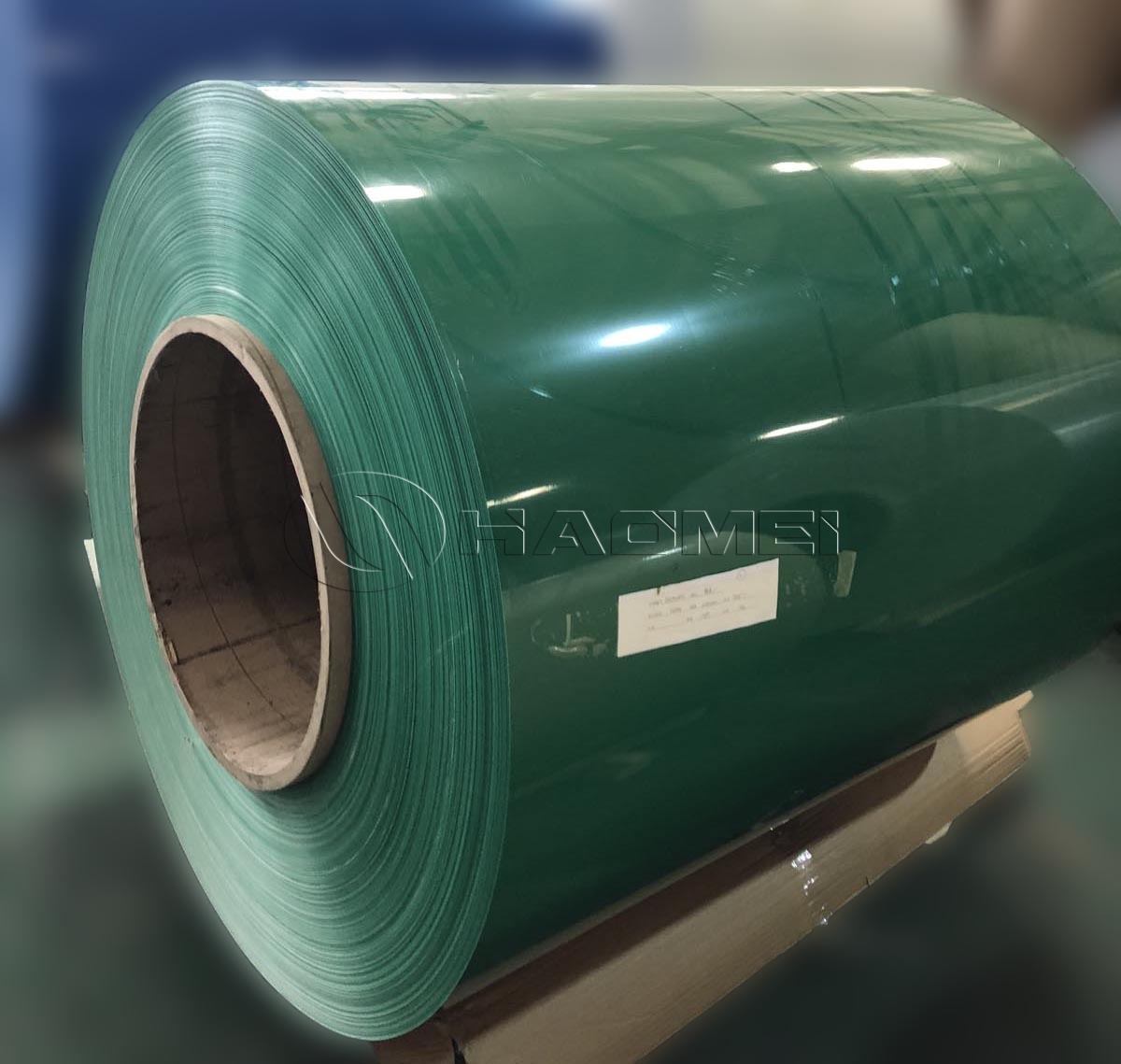

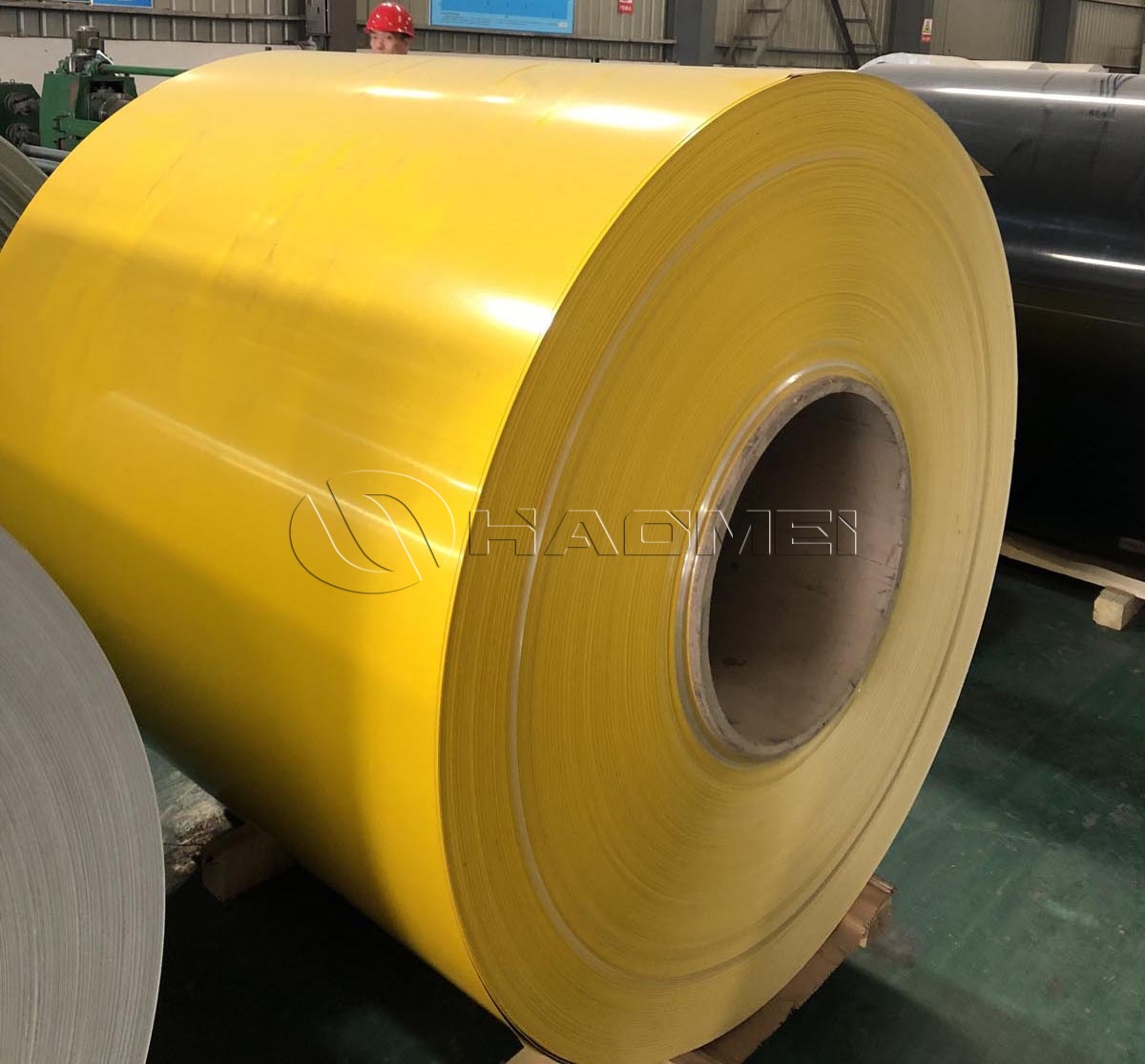

In the rapidly evolving field of automotive design, the rise of lightweight materials and high-end aesthetics has positioned aluminum as a leading material for interior innovation. HAOMEI Aluminum recommends 1100 color-coated aluminum coils, which combine functionality and visual appeal, making them the preferred choice for designers and manufacturers.

1100 color-coated aluminum coils are made from 1100 series aluminum alloy and treated with PE or PVDF color coatings. With an aluminum content exceeding 99.0%, 1100 alloy features low density, high plasticity, and excellent corrosion resistance, making it ideal for applications requiring both lightweight and aesthetic appeal. After color coating, the material retains its physical properties while offering a wide range of color options, from metallic grays to vibrant reds, with customizable matte or glossy finishes.

Coating Process

1.Pre-treatment: The aluminum surface is cleaned, degreased, and chemically converted to form a dense protective layer, ensuring strong adhesion of subsequent coatings.

2.Coating System: Typically a multilayer structure:

Primer: Enhances adhesion and provides corrosion protection.

Topcoat: Delivers the final color, gloss (high gloss, matte, metallic, special textures), and primary weather resistance and UV protection.

Clear coat: The outermost layer provides high hardness (commonly measured by pencil hardness), scratch resistance, chemical resistance (against sweat, cleaning agents, etc.), and easy-to-clean properties.

3.Curing: Coatings are baked at precisely controlled temperatures, ensuring optimal crosslinking and performance.

Advantages of 1100 Color-Coated Aluminum Coils for Automotive Interiors

Excellent Formability

1100 aluminum alloy exhibits high plasticity and elongation, making it resistant to cracking during stamping, bending, and rolling. It is ideal for producing complex shapes and curved interior trim components.Strong Decorative Appeal

The color coating process enables a variety of decorative finishes, including high gloss, matte, brushed metallic, wood grain, and stone textures. Color options cover RAL standards or custom colors, allowing differentiation for various vehicle models and brands.Lightweight

Compared with traditional steel or some plastic composites, color-coated aluminum coils are low-density with high strength-to-weight ratio, reducing overall interior weight while maintaining structural stability. This supports lightweight vehicle design, aligning with trends in new energy and energy-efficient vehicles.Excellent Corrosion and Aging Resistance

The coating not only enhances aesthetics but also protects against moisture, oil, and chemical exposure, keeping the aluminum substrate stable under temperature variations and harsh interior conditions.Environmentally Friendly and Recyclable

Aluminum is 100% recyclable, supporting sustainable automotive manufacturing. High-quality coating systems also achieve low VOC emissions, meeting interior environmental standards.

Technical Specifications of 1100 Coated Aluminum Coils

| Alloy | 1100 |

| Aluminum content | ≥ 99.0% |

| Temper | O / H14 / H24 (customized per forming requirements) |

| Thickness range | 0.2 - 1.2 mm (commonly 0.3 - 0.8 mm for interior parts) |

| Width range | 100 - 1600 mm |

| Length range | 100 - 16,000 mm |

| Inner diameter | 405 mm / 505 mm |

| Tensile strength | ≥ 90 MPa |

| Elongation | ≥ 25% (O temper) |

| Color | RAL standard / custom colors |

| Surface effect | Wood grain, stone texture, brick, camouflage, etc. |

| MOQ | 1-3 tons |

Application Areas

1100 color-coated aluminum coils are widely used in automotive interior components, including but not limited to:

Instrument panels and center console trim

Door interior trim strips

Armrest and edge covering materials

Interior functional component surface coverings

Premium metallic decorative parts for high-end models

Coating Advantages

High-performance PE or PVDF coatings applied to aluminum coils create multiple color, texture, and gloss effects. The multilayer coating ensures long-term durability inside the vehicle cabin:

UV Resistance: Prevents fading or yellowing under intense sunlight.

Fingerprint Resistance: Special surface treatments maintain cleanliness even under frequent touch.

Corrosion Resistance: Protects aluminum from moisture and cleaning agents.

Color Consistency: Advanced roll-coating ensures perfect match between door trims and dashboard panels.

-

1000 Series Aluminum Coil Coating Process

1000 series color coated aluminum coil is positioned as a high-purity, highly formable substrate for stable appearance and corrosion resistance after coating.

2026-01-19

-

1000 Series Color Coated Aluminum Coil For Roofing

1000 Series color coated aluminum coil for roofing is positioned as a lightweight, high-corrosion-resistance roof stock for roll-formed panels, corrugated sheets, ridge caps, flashings, and rainwater systems.

2026-01-19

-

Matte Finish 1000 Series Color Coated Aluminum

Matte finish 1000 series color coated aluminum coil with PE/PVDF options, clean forming, and stable color for trim, ceilings, and lightweight panels.

2026-01-20