News

By Hermione

By Hermione

5052 Color Coated Aluminum Coil for Shipbuilding

In modern shipbuilding, lightweight design, high strength, and corrosion resistance are the primary criteria for material selection. Compared with traditional steel, aluminum materials can reduce vessel weight by up to 50%. When combined with advanced coating systems, 5052 color coated aluminum coil not only preserves this lightweight advantage but also delivers long-term corrosion protection and enhanced aesthetic value, making it an ideal solution for marine applications.

Introduction to 5052 Coated Aluminum Coil

5052 aluminum alloy is a typical Al-Mg marine-grade aluminum alloy, with aluminum (Al) and magnesium (Mg) as its main alloying elements. It is well known for its excellent corrosion resistance and good formability.

Color coated aluminum coil is produced by applying surface treatments, including cleaning, chemical pretreatment, anti-corrosion primer, and decorative color coating onto 5052 aluminum coil. This process maintains the alloy's mechanical properties while significantly improving surface protection and visual appearance.

Temper Conditions

5052-O (Annealed): Excellent formability, suitable for components with complex curves.

5052-H32: A balanced combination of strength and formability; the preferred choice for most hull plates and structural components.

5052-H34: Higher strength, suitable for areas subjected to greater mechanical stress.

Why Choose 5052 Aluminum Alloy?

Outstanding Salt Spray Resistance

In high-salinity and high-humidity marine environments, 5052 forms a dense and stable oxide layer that effectively resists chloride ion attack, outperforming common 1xxx and 3xxx series alloys.No Stress Corrosion Cracking (SCC)

This is a critical advantage for marine structures, ensuring reliability under combined tensile stress and corrosive conditions without sudden brittle failure.Energy Efficiency

Aluminum has only one-third the density of steel. Reducing vessel weight directly lowers fuel consumption while increasing speed and payload capacity.Excellent Fabrication Performance

5052 marine aluminum offers good cold workability and formability. It performs well in bending, stamping, and welding, meeting the demands of complex ship structures and interior designs.

Technical Specifications of 5052 Coated Aluminum Coil

| Alloy | 5052 |

| Temper | O, H32, H34, H38, etc. |

| Thickness | 0.3-6.0 mm |

| Width | 100-2650 mm |

| Length | 1000-16000 mm |

| Coating | PE, PVDF, etc. |

| Certification | ABS, DNV, CCS and other classification societies |

| MOQ | 1-3 tons |

Mechanical Properties

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Typical Applications |

| O | 193 | 90 | 22-30 | Deep-formed complex components |

| H32 | 228 | 193 | 12-18 | Hull plating, deck panels |

| H34 | 262 | 214 | 10-14 | Higher-strength structural areas |

| H38 | 290 | 225 | 7-8 | High-stress zones |

Performance Advantages of 5052 Prepainted Aluminum Coil

Superior Corrosion Resistance

The high magnesium content provides natural seawater resistance. Combined with protective coatings, long-term durability in marine environments is ensured.Excellent Workability

Good ductility and flexibility allow cold bending, stamping, forming, and welding for structural and decorative ship components.Lightweight with Adequate Strength

Mechanical properties support lightweight ship design, improving fuel efficiency and operational performance.Decorative Appeal

Multiple color options and surface finishes meet both exterior styling and interior design requirements.Weather Resistance

PVDF and high-quality PE coatings offer UV resistance, oxidation resistance, and color stability in harsh marine conditions.Environmental Sustainability

Aluminum is 100% recyclable, aligning with green shipbuilding and sustainable development goals.

Coated Aluminum Coil Details

1. Coating Types

| Coating Type | Features | Typical Applications |

| Polyester (PE) | Wear-resistant, scratch-resistant, cost-effective | Interior structures, non-load-bearing parts |

| Polyurethane (PU) | High temperature and chemical resistance, excellent color stability | Hulls, bridges, decks |

| PVDF | Ultra-durable, UV-resistant, 20+ years color retention | Luxury yachts, naval vessels |

| Quartz Coating | Ultra-high temperature resistance (>200°C) | Industrial and chemical vessels |

2. Core Value of Prepainted Coatings

Aesthetic Appeal: Over 100 color options for customized vessel branding.

Protection: Prevents oxidation, corrosion, and surface degradation, extending service life.

Cost Efficiency: Typical coating thickness of 20-25 μm reduces costs by approximately 30% compared with traditional spray painting.

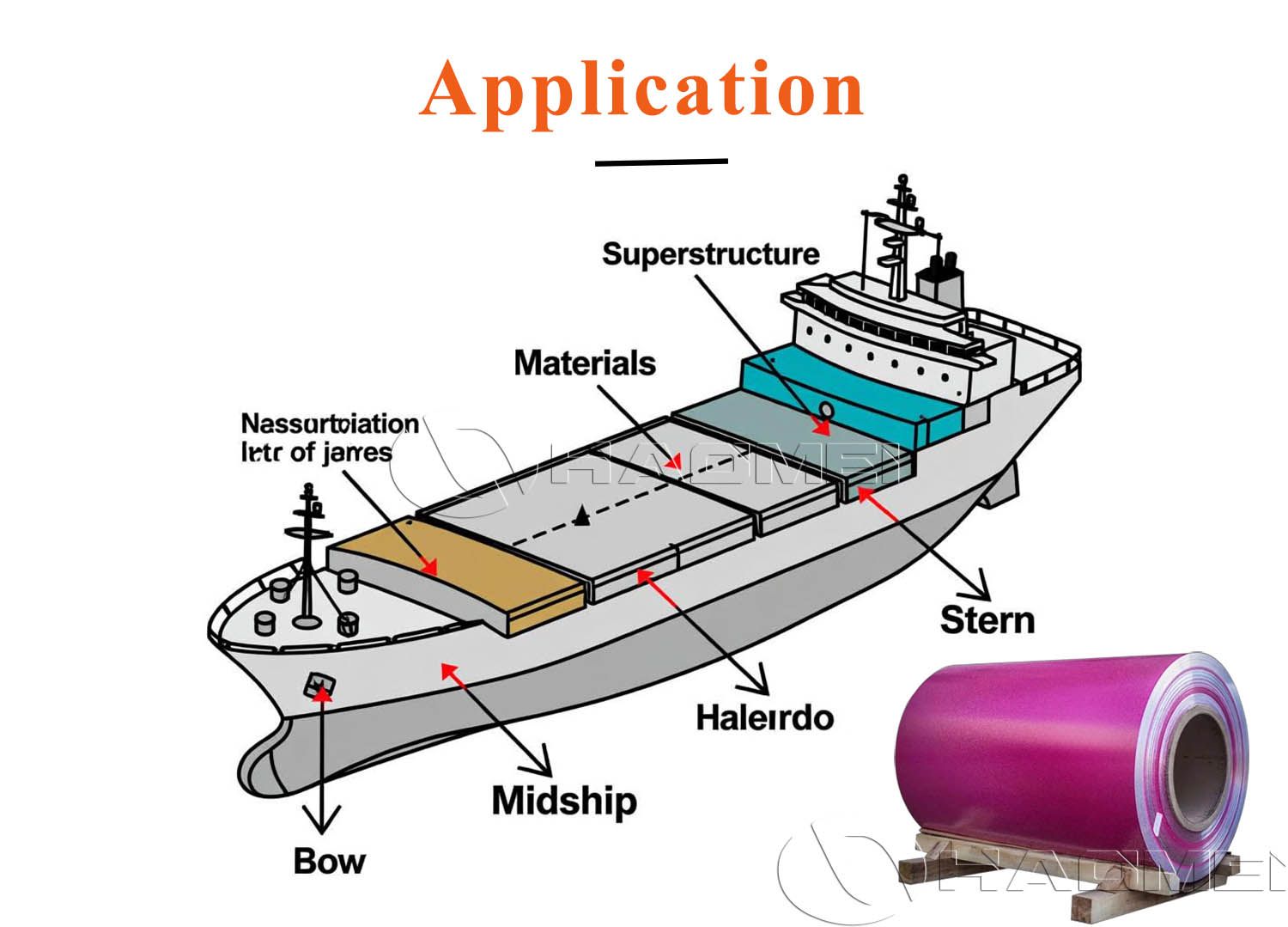

Application Areas

Hull Structures and Outer Shells:

H32 or H34 prepainted 5052 aluminum coil reduces vessel weight, increases cruising speed, and lowers fuel consumption.Interior Bulkheads, Ceilings, and Decorative Panels:

O or H32 temper offers excellent formability for curved designs, while coatings provide fire resistance, mildew resistance, and easy cleaning.Superstructures:

Wheelhouses, cabins, and accommodation areas benefit from weight reduction, lowering the vessel's center of gravity and improving stability.Marine Interiors:

Various colors and textures help create comfortable, modern onboard environments.

Comparison with Other Materials in Shipbuilding

| Material | Advantages | Disadvantages |

| Stainless Steel Plate | Higher strength | Heavy, expensive, difficult to form |

| Standard Aluminum Plate | Lower cost | Limited corrosion resistance, lower strength |

| Carbon Fiber Panels | Ultra-lightweight | Extremely high cost, unsuitable for large structures |

-

Pe Coated Aluminum Coil Vs Pvdf

Compare PE coated aluminum coil and PVDF coated aluminum coil by resin chemistry, coil coating process, durability, color retention, and end uses.

2026-01-27

-

5052 Color Coated Aluminum Coil for Exterior Walls and Roofing

5052 PVDF-coated aluminum coil features an exceptionally stable fluorocarbon chemical structure, giving it outstanding weather resistance, UV resistance, and color-retention performance, making it especially suitable for architectural applications that re

2025-12-09

-

China 1050 / 1100 / 1200 / 3003 / 3004 Color Coated Aluminum Coil for Roofing

1050, 1100, 1200, 3003, and 3004 color coated aluminum coils are widely used in roofing panels, wall panels, corrugated roofing sheets, and architectural façade decoration.

2025-12-29